Sheeters

Synchro-Fly Sheeter Technology

The Synchro-Fly SC and SF-C Series Sheeting Technology Solutions

Designed for excellence in precision paper cutting worldwide, our synchro-fly sheeting solution provides you with accuracy in cuts required by any conversion or finishing process. Designed with production in mind, The Synchro-Fly SC and SF-C Series Sheeters are a flexible sheeting solution that are easy to setup, easy to operate, and provides competitive production capabilities at a fraction of the capital costs of European and American counterparts. Models come in 1400 to 2800 mm and are available in full or compact versions.

The design philosophy is to use standard parts readily available off-the-shelf from major global suppliers such as Festo, Siemens, Tidland, Dines, etc… Our sheeting technologies offer state of the art automatic off-load system that enables continued production without the need to stop for skid change outs. The increase in production by two to three minutes per skid change will be realized at your bottom line profits while decreasing the ROI down to approximately 24 months. With over 800 sheeters installed worldwide, our SC Series is a robust and reliable cost effective machine with easy operational interface technologies that will provide effective sheeting with the highest accuracy.

Single Rotary Sheeter Technology

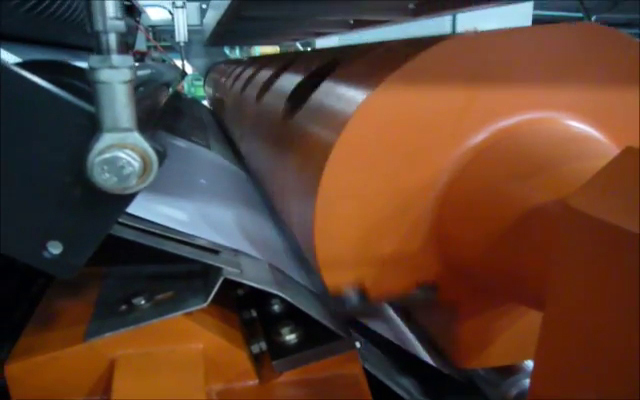

The Single Rotary (Dead Knife) DK Series Sheeting Technology Solutions

Designed for excellence in precision paper cutting worldwide, our sheeting solutions provide you with accuracy in cuts required by any conversion or finishing business that relies of quality converting equipment. The cutting system in this series of sheeting technology is our dead knife (single rotary) knife configuration. High-Speed Steel (HSS) sheeter blades are installed in the cutting system that consists of a rotating drum against a lower fixed bed knife creating a perfect scissor-type cutting action..

Models include the standard configuration, cut-to-register configuration and our compact configuration. These systems are available in full and compact sizes depending on floor space availability. Overall there are five standard width systems ranging from 1400 to 2800 mm. Custom configurations are also available and determined in the pre-order configuration process. Leigh Sheeting & Converting USA offers a wide range of sheeting solutions and converting equipment to fit any niche or need your business needs. From single rotary, dual rotary to slitting rewinding technologies, call Leigh USA today for a solution for your converting needs.

Duplex Sheeter Technology

The Duplex DS Series Sheeting Technology Solutions

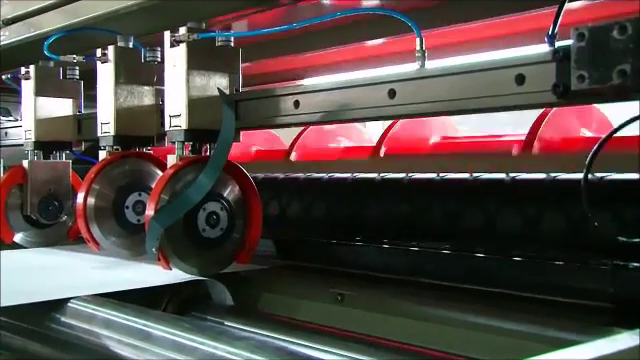

Designed for excellence in precision paper cutting worldwide, our sheeting solutions provide you with accuracy in cuts required by any conversion or finishing business that relies of quality converting equipment. This sheeter system is a multi-format based solution with 2 transversal cutting systems that can be configured for the same width or different widths. The stacking process is also configured for different formats and are auto leveling. This sheeting solution is easy to setup, flexible and easy to operate compared to expensive alternatives that may produce similar results at best.

Our Duplex Sheeting solution offers you the ability to sheet paper/board at different lengths and widths depending on your customer requirements. Designed for easy use, this solution features leading cutter head design to give your equipment an increased speed curve and increased production for your business. This solution is higher end and comes with an advanced overlap and stacker section to provide seamless production of a variety of grades. We offer two standard models in a 1900 and 2800 mm format. From single rotary, dual rotary to slitting rewinding technologies, call Leigh USA today for a solution for your converting needs.

Our Innovations

Industry Focused Products!