RKB Splice Detectors

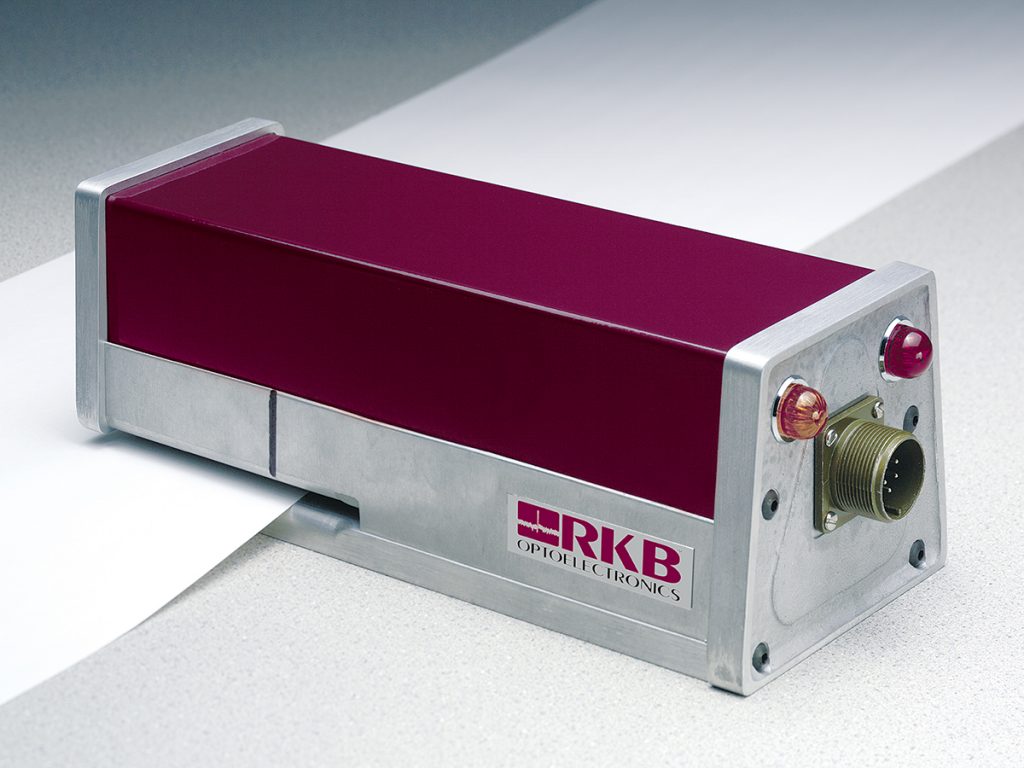

Model 1032 Classic® Splice Detector™ Technology

The Model 1032 Classic® Splice Detector™ Technology is our original patented solution for the detection of all types of splices in non-metallic web based processes. It can monitor one or multiple webs of material up to a total thickness of 0.175″ (4.445 mm) thick at one common installation point thus facilitating ONE unit for any inspection application. This technology is self calibration to any new process condition and is not affected by speed, colors, caliper, or printing. It can be mounted at any position along the web edge in the machine provided the material runs parallel through the inspection aperture. The unit comes with an indication marking showing the position of the web edge which should be about 0.5″ ( 12.7 mm) inches beyond to allow for web wander. It is powered by 120/220 VAC, 50/60 Hz, Single Phase. This system can be applied to any web based format where critical splice detection is required. Whether used for end product quality or controlling nip points, coating heads, printing heads, this unit will provide reliable, accurate and consistent detection of all splices to ensure your goals for quality and control are met 24/7.

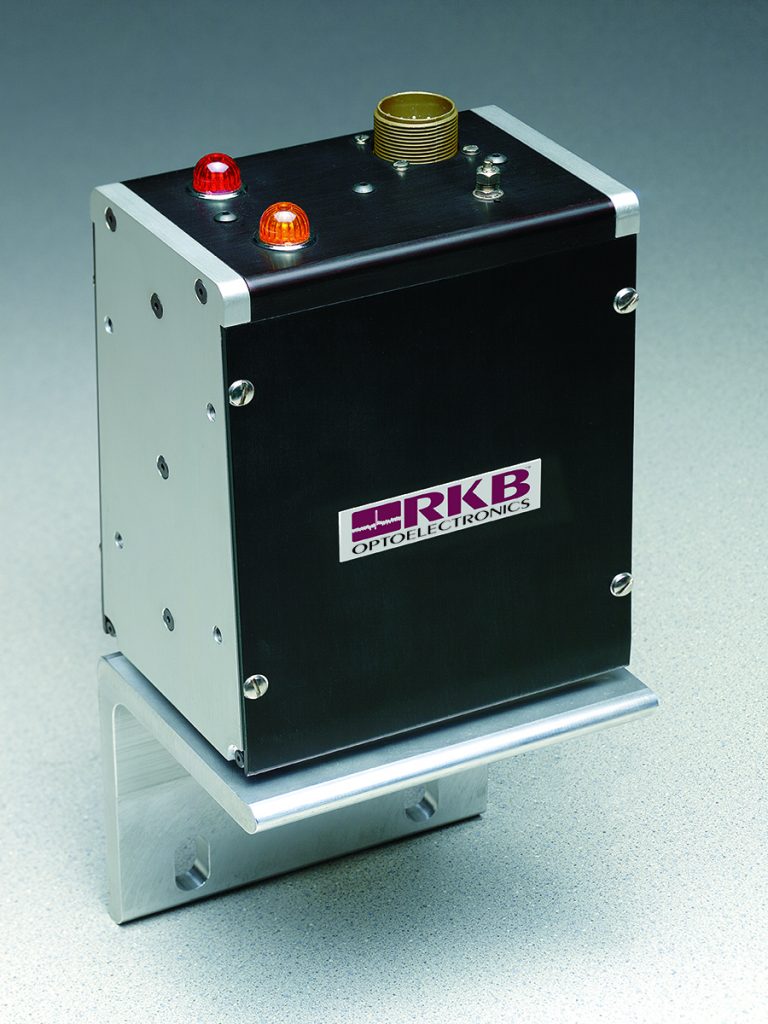

Model 1032B Classic® Splice Detector™ Technology

Based on our original Model 1032 sensing technology, the Model 1032B Classic® Splice Detector™ Technology was developed for center mounting and can be applied to any non-metallic material process line where critical splice detection is required. Since this technology mounts center of web, it eliminates the need for any operational intervention and can be applied more effectively on processes where deckle (width) changes are common. Installation is easy and the two pieces (Sensor and Base Plate) should be securely fastened towards the center of the process that allows the material to pass through the aperture created in a parallel manner. This solution will monitor one to multiple webs of material at one point provided the total thickness does not exceed 0.2″ (5.08 mm). It is powered by 120/220 VAC, 50/60 Hz, Single Phase.

Like the Model 1032, the 1032B provides two types of outputs. One is a digital pulse output of 15 VDC and/or a dry contact relay that will accept anything voltage from 5 VDC through 220 VAC depending on what you are controlling. This technology is self calibrating and is not affected by material speed, color, caliper, or printing. The plug connection is identical to the Model 1032 and thus makes upgrading from an edge mount unit to a center mount very easy with limited downtime. This solution will detect any known splice fault @ any knows production speed guaranteed! With over 6000 installation worldwide, our splice detection solutions are the standard used worldwide in papermaking, winding, printing, coating, cutting, laminating, and film processes. The ROI averages to 24 hours once installed with an average operational life expectancy of 30 years before any maintenance is required.

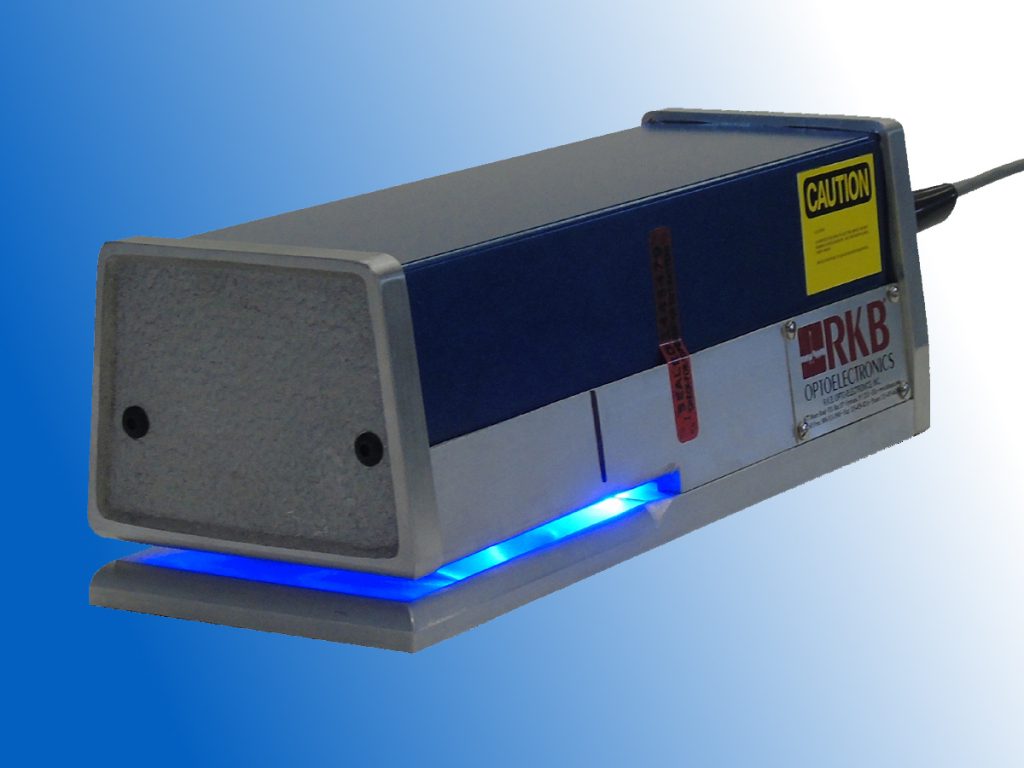

Model 1088 Sentinel® Splice Detector™ Technology

The Model 1088 Sentinel® Splice Detector™ Technology was developed under our green initiatives. This technology is an edge of web mounted solution for non-metallic web based processes. Like it’s cousin, this solution will monitor one to multiple webs up to a total thickness of 0.175″ (4.445 mm) @ any known production speed. It is self calibrating and is not adversely affected by speed, material color, material type, caliper, or printing. As an all in one unit, it is very easy to install anywhere along the process machine where critical splice detection is required. Powered by 24 VDC this technology will provide you with a digital pulse output of 5, 12, 15 or 24 VDC @ a time constant of of 0.01, 0.1 or 1.0 seconds. The output can be high to low or low to high and is selectable depending on your operational requirements. This solution will provide years of operation before any maintenance requirements kick in and provides an average ROI within 24 hours. Unlike photo cells or ultrasonics type sensors, you only need one of these systems to handle your process and eliminate any operational intervention on grade changes.

Model 1088B Sentinel® Splice Detector™ Technology

The Model 1088B Sentinel® Splice Detector™ Technology is the sister solution to the Model 1088 and mounts center of web. It is designed to monitor non-metallic web based materials of all types. This solution will monitor one to multiple webs up to a total thickness of 0.200″ (5.08 mm) @ any known production speed. It is self calibrating and is not adversely affected by speed, material color, material type, caliper, or printing. It is very easy to install anywhere within the process machine where critical splice detection is required. Powered by 24 VDC this technology will provide you with a digital pulse output of 5, 12, 15 or 24 VDC @ a time constant of of 0.01, 0.1 or 1.0 seconds. The output can be high to low or low to high and is selectable depending on your operational requirements. This solution will provide years of operation before any maintenance requirements kick in and provides an average ROI within 24 hours. Unlike photo cells or ultrasonics type sensors, you only need one of these systems to handle your process and eliminate any operational intervention on grade changes.

Black Mamba® Web Press Splice Detector™ & Distribution Technology

The Model 1032BM and Model 1088BM Black Mamba® Web Press Splice Detector™ & Distribution Technology was developed for high speed digital web press solutions to ensure all known types of splices can draw through the printing press without damaging sensitive print heads and other components. Originally developed with HP, this solution is implemented just after the unwind roll prior to the first print head station. Unlike the standard solution, this technology has been modified to provide analytics to the press operations to facilitate the passage of splices through each print head station thus negating any damage to the expensive print heads. Mounted center of web, this solutions will facilitate any web press no matter the deckle width. They are self calibration sensors that are not affected by material type, material color, splice tape color, speed, caliper or printing. This technology can be provided to run off 120/220VAC, 50/60 Hz, Single Phase or 24 VDC. The output provided is set to 5 VDC digital pulse at 100 milliseconds but can be modified. Built in diagnostics will allow the end user to ensure the system is operational at all times.

Model 1090 Sentinel® (Narrow Web) Splice Detector™ Technology

Model 1090 Sentinel® Splice Detector™ Technology was developed as a lower cost alternative for narrow web processs such as machines like Mark Andy. They are based on our Model 1088 technology, but modified for narrow web applications. The unit will monitor one to two webs of non-metallic material to include laminates. Like all our technology, the Model 1090 is a self calibrating unit and will monitor materiel webs at any known process speed. This technology is not affected by printing, material color, caliper or speed and operates off 24 VDC primary. The output is selectable and can be set for 5, 12, 15 or 24 VDC digital pulse @ 0.01,0.1 or 1.0 seconds in duration. The signal can be high to low or low to high depending on your requirements for process control. This unit has been designed to mount on the edge of the web material or center mount to the process.

Model 1280 Guardian® Multicolor Edge Marking™ Technology

The Model 1280 Guardian® Multicolor Edge Marking™ Technology is a system designed to mark the edge of web material. It can be provided in one to five colors standard and comes equipped with a rodless cylinder that facilitates a 12″ stroke travel (additional travel can be provided). The spray head assembly is completely enclosed eliminating any potential over-spray from landing on the web and an over-spray collection system which is not available with other systems. The technology can be implemented with any web based inspection system from any supplier worldwide.

The system comes with automatic web tracking which is done by monitoring the edge of the material and will track forward and reverse continually to compensate for web travel. The main spray function utilizing low PSI pressure and will spray a suitable amount of colored ink, or any liquid, onto the web edge to identify the area of concern. The technology can be setup to spray relative to type of defect or application type such as a treater, coater being offline. The ink will be seen as concentric circles once the end material roll is moved to additional processing. Utilizing gravity control functions for ink supply, we ensure lower cost maintenance is achieved as compared to other solutions.

The overall design allows for a footprint of 4″ (10.16 cm) in the machine direction for installation and can be tied directly to any inspection solution or process equipment for activation. Components in the ink delivery system are made of stainless steel and are very durable in that type of acidic environment. With costs well below competitive alternatives, the Model 1280 will deliver reliable and accurate operation 24/7. This technology comes with a mounting sole plate that is adjustable enabling precise alignment to the web process for which is applied to. Custom configurations are available upon request.

Model 3600 OPTOMIZER® FCS Sheeter Inspection™ Technology

The Model 3600 OPTOMIZER® FCS Sheeter Inspection™ Technology was originally introduced as our Model 3030. It was developed specifically for sheeter applications to ensure sheeted material, especially coated papers and board, were defect free. It will monitor a signal web of material for holes, dirt, bugs, scale, coat skips, coating streaks, scratches and other anomalies. Mounted prior to the slitting and knife section, the system will output to your PLC the appropriate signal for reject gate activation thus ensuring the stacked product is defect free prior to shipment. Utilizing state of the art sensors and lighting techniques, this system will detect scratches as small as 0.002″ (0.00508 mm) in width and autonomous occurrences as small as 0.001″ (0.00254 mm) diameter. If you require ISO certification of product quality, let our Model 3600 do the job for you.

Our Innovations

Industry Focused Products!